As the largest composites show in the world comes to a close for another year, what was it all about?

Primarily, it is the one place where you get to see industry trends, clever ideas as well as catch up with existing and new customers.

Primarily, it is the one place where you get to see industry trends, clever ideas as well as catch up with existing and new customers.

| Thermoplastics are 'Trending' As expected, there is a concerted effort to get the benefits of composite materials into mass produced vehicles, but uptake has been slow to date. Even personnel in the automotive sector really don't know where the materials will be applied. What was apparent this year are the vast number of examples of thermoplastic composite parts and hybrid thermoplastic/metal/composite parts. Many of these use carbon in various forms, from recycled materials, to short fibre sheet moulding compounds and long fibre pre-forms. |

However inspiring all the parts on display were, they all seemed to be missing the key issue with the automotive sector, 'Recycling'. The upshot is that there has been a lot of development in medium to high volume manufacturing of composites, which will benefit all industry sectors.

What was Missing?

The industry sector that is the most promising for composite materials is the construction industry. Having completed a number of projects related to this industry over the last few years, this sector far outweighs the aerospace and automotive sectors in terms of volume of materials.

With the increased level of fire retardant resin systems, we are awaiting the boom in this sector and expected to see more developments on display.

On a more selfish note, we are in the middle of a large house extension and what is apparent is the potential for composite materials.

The industry sector that is the most promising for composite materials is the construction industry. Having completed a number of projects related to this industry over the last few years, this sector far outweighs the aerospace and automotive sectors in terms of volume of materials.

With the increased level of fire retardant resin systems, we are awaiting the boom in this sector and expected to see more developments on display.

On a more selfish note, we are in the middle of a large house extension and what is apparent is the potential for composite materials.

What we are actually seeing is a lack of knowledge, poor presentation and perceived threat (to the existing material producers). Combined with a lack of experience with composites, and the trust which comes from this, it is a real concern.

Just evaluating cladding systems for a building has resulted in finding composite sandwich panel structures (that are really effective) which have become unavailable through company buy-outs and product line closures. It seems that some are already aware of the upcoming threats. When a company has invested millions in the development of a product, they don't want it washed away by competitors. In our experience, composite building products have a slightly higher initial investment over traditional materials but have a much longer service life and reduced maintenance costs, but only time will tell. It's not 'IF' it will happen, it's just 'WHEN' will it happen?

Just evaluating cladding systems for a building has resulted in finding composite sandwich panel structures (that are really effective) which have become unavailable through company buy-outs and product line closures. It seems that some are already aware of the upcoming threats. When a company has invested millions in the development of a product, they don't want it washed away by competitors. In our experience, composite building products have a slightly higher initial investment over traditional materials but have a much longer service life and reduced maintenance costs, but only time will tell. It's not 'IF' it will happen, it's just 'WHEN' will it happen?

New Materials

On a more positive note, there are always a few really 'WOW' mentions from these shows and these are this years (for us at least!):

| Triaxial Woven Fabrics For all of us that have the issue of dealing with double curvature and draping fabrics (easily and consistently) over complex 3D mould, this could be something of interest. | Woven on looms with 2 warps, which can run in different angles, results in a hexagonal weave construction that can better accommodate double curvature. Providing fibres at 60 degrees increments, rather than 90 degrees, gives a much more compliant material, and here are some images to show you. Weblink is www.sakase.co.jp |

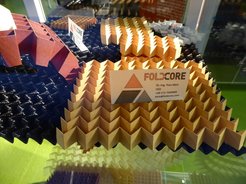

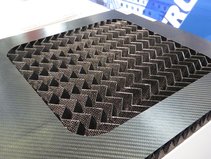

| High Tech Origami Fed up with having to select a core material from a range of standard materials but nothing quite hits the mark? Using simple origami techniques, FOLDCORE can turn any sheet of material (from paper to metal to carbon) into a core material that can vary in density and accommodate changing curvature. Right now, their website does not do them justice, so the images below will assist. It's such a great idea for shipping, strength and usability as well as providing solutions such as drainage where required. |

Off the Shelf Nano

Why is small important? Well as we all know, fibre content can really assist specific structural & electrical requirements and getting down to the microscopic level can have a big influence. Ocsial.com have a range of matrix materials as well as carbon nano-fibres 'in a jar' ready to infill into your own matrix/part. We could have really done with this material a few months ago on a specific project and we can see ourselves using it in the near future on a number of projects. Oh well, you always find what you need after you need it!

Why is small important? Well as we all know, fibre content can really assist specific structural & electrical requirements and getting down to the microscopic level can have a big influence. Ocsial.com have a range of matrix materials as well as carbon nano-fibres 'in a jar' ready to infill into your own matrix/part. We could have really done with this material a few months ago on a specific project and we can see ourselves using it in the near future on a number of projects. Oh well, you always find what you need after you need it!

Warm Carbon Fibre

Lamina Heat now produce a carbon fibre heat mat that allows a much more uniform distribution of heat over traditional electric heating. Applications include mould heating, repair curing (and better electric underfloor heating!) A demand that far outweighs mould heating and falls into the realms of high volume use of an unusual composite materials in the construction industry! We expect you'll see this across lots more fields...

If you went to the show we hope you had a productive week. We enjoyed catching up with everyone, same time same place next year!

RSS Feed

RSS Feed