|

Typical Attendees

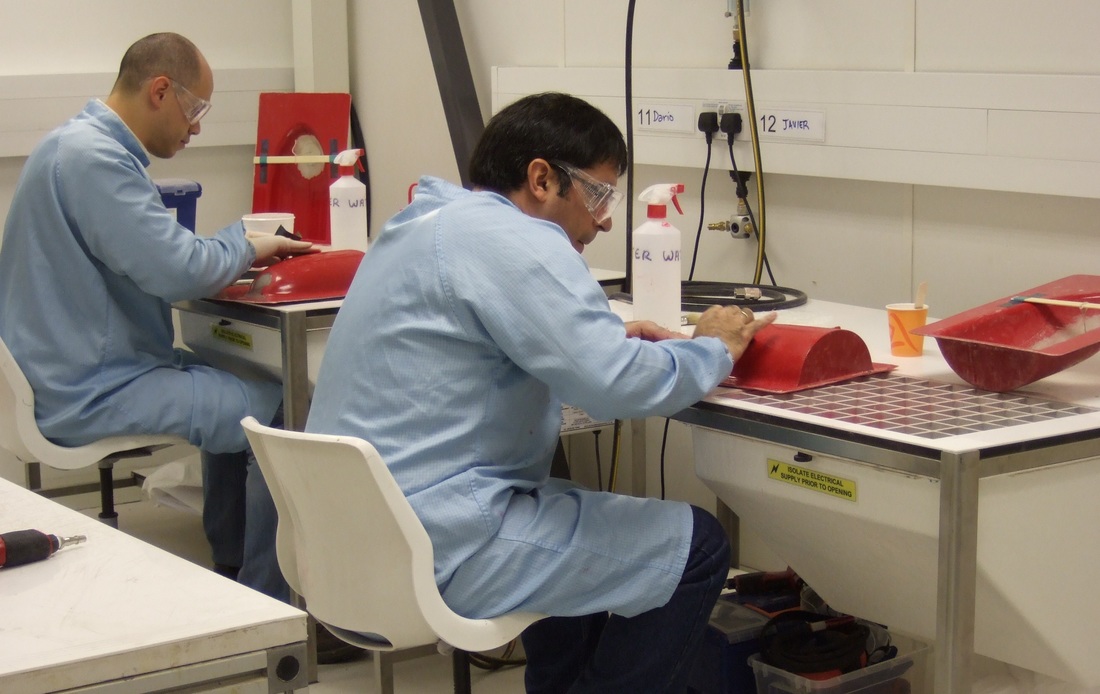

This course is suitable for anyone involved with repairs to composite materials, including repair technicians, supervisors, engineers, designers, researchers and managers. Pre-requisite Attendees must have previously completed the course DMSC58, Composite Repair - Stage 1 Structure 25% theory, 75% practical, 12 delegates maximum Price per Delegate

£ 2,400.00 (£ 2,000.00 plus £400 VAT) |

|

Special Notice

As training providers it is our responsibility to ensure training is up to date and taught to the highest standard. To assist with this we have aligned our repair courses with the requirements of the SAE’s AIR4938 standard, 'Composite and bonded structure technician/specialist training document'. This standard was produced by the worldwide 'Commercial Aircraft Composite Repair Committee' (CACRC) and defines the foundation content and structure for composite repair training that is applicable to all industry sectors.Our stage 1 and 2 composite repair courses already covered cross sector repair techniques with a full range of materials, processes, tools and techniques and were already 90% in line with the AIR4938 standard. As all our courses are already in line with the UK’s National Occupational Standards for composites and fully documented to the UK’s Qualifications and Curriculum Authority requirements, it was a relatively easy task to cross reference to the AIR4938 standard and add 10% more technical content to our repair courses. The end result is that all our customers benefit from the work we do for aerospace.

Composite repair 2 course content

| DMSC59 | Session 1 09:00 - 11:00 |

Session 2 11:15 - 13:15 |

Session 3 13:45 - 15:45 |

Session 4 16:00 - 18:00 |

|---|---|---|---|---|

| Monday | Introduction Equipment issue Theory & Discussion Advanced composite repairs Co-bonding & secondary bonding structural repairs Structural repair design and processes |

Theory, Demo & Practical Refresh of composite,materials & processes On tool extraction, dust containment and capture strategies Advanced dust control & dust free material removal |

Theory, Demo & Practical Pre-preg material life, storing & defrosting Ply orientation standards notation & Variations Nesting & kitting Spring back, distortion Balanced & un-balanced orientated plies |

Theory Adhesion & release Release agents Adhesive Bonding Peel plies Demo & Practical Production of a pre-preg panel to production documentation |

| Tuesday | Theory, Demo & Practical Sandwich panels & multistage processing Core materials & tracer films Preparation & application of honeycomb core Second stage curing of pre-preg panel |

Theory, Demo & Practical Human Factors Damage inspection & evaluation Damage reporting Structural repair design considerations |

Theory, Demo & Practical NDT inspection overview & techniques Setting up and using NDT equipment NDT inspection of undamaged parts |

Practical NDT Inspection of damaged parts Production of inspection report Design of standard step sanded repair scheme |

| Wednesday | Theory, Demo & Practical Conducting laminate discovery activities using ‘Step Sanding Tool Kit’ Fibre, fabric, orientation & thickness records |

Theory, Demo & Practical Prepare step sanded repair surface for type B wet lay- up part using Step Sanding Tool Kit |

Theory, Demo & Practical Fibre to resin ratios Ply thickness calculations and variation De-bulk factors Bleed variation Calculation of bleed plies |

|

| Thursday | Theory, Demo & Practical Prepare and apply materials to the repair surface Wet lay-up laminate repair using double membrane vacuum bag with bleeder plies |

Theory, Demo & Practical Tg point of parts Using infra-red lamps & temporary ovens for curing Positioning of thermocouples Recording of cure profile |

Theory, Demo & Practical Producing and using standard repair patches Pressure de-bulk of repair patch |

Practical Prepare step sanded repair surface for type A pre-preg part using Step Sanding Tool Kit |

| Friday | Theory, Demo & Practical Selection and sequence of vacuum bagging consumables Theory, Demo & Practical Apply standard repair patch & vacuum bag |

Theory, Demo & Practical Using hot bonders & heat mats, for on part curing Positioning of thermocouples Determination & monitoring of cure profile |

Discussion & Practical Inspection, evaluation and review of repairs completed Completion of repair reports Destructive testing and inspection of repairs completed |

Reinstate Workshop Written test Equipment return Summary / Feedback |

| DMSC59 Composite Repair Stage 2.pdf | |

| File Size: | 177 kb |

| File Type: | |

Composite Repair – Stage 2 course details:

This is aimed at anyone involved with repairs to composite materials, including repair technicians, supervisors, engineers, designers, researchers and managers.

This is aimed at anyone involved with repairs to composite materials, including repair technicians, supervisors, engineers, designers, researchers and managers.

|

Attendees must have previously completed the course DMSC58, Composite Repair - Stage 1. At the start of the stage 2 course we begin with a 30 minute recap of what was covered on the Composites Repair – Stage 1 and then cover approximately 30 hours of practical and 10 hours of new theory and technical demonstrations. |

|

You will produce one component yourself in line with the SAE’s AIR4938 standard, 'Composite and bonded structure technician/specialist training document'. This standard was produced by the worldwide 'Commercial Aircraft Composite Repair Committee' (CACRC). Your second component will be supplied by us to ensure that everyone attending the course has consistent components to work with.

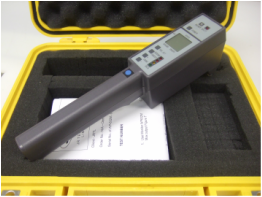

You will begin by inspecting your composite components using a range of Non Destructive Testing (NDT) techniques. These include tap test using a wood pecker, moisture meter and ultrasonic inspection. |

The composite parts are inspected before and after applying controlled damage. This is designed to mimic the real life damage a component might incur during normal service. You will be shown what to expect to find when inspecting a composite component and how the various types of damage are categorised.

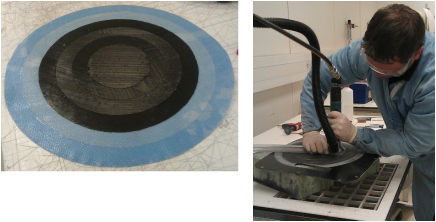

Working with the Step Sander Repair Kit, you will complete discovery exercises (investigating damage and ply lay-up) and then learn how to effectively remove damaged composite material prior to repair.

The Step Sander Repair Kit has been developed to improve the quality and consistency of the repair surface by working with jigs, offering a high level of accuracy (0.05mm in depth). As you become more familiar with the equipment, your speed will increase. It will allow you to produce a higher quality step sanded repair, in a shorter period of time, than with alternative tools.

We will cover laminate calculations to give accurate resin to fibre ratios. This will ensure material consistency through the parent material and the repaired area, maintaining material thickness and fibre content, essential in good quality repair.

|

Various curing methods are used through the week, demonstrating their effectiveness and advantages in various situations. Surface and envelope vacuum bagging techniques are used with a range of curing methods. These curing methods include using a hot bonder with heat blankets and infrared lamps, autoclave and oven.

|

The repaired components are checked using the NDT equipment and then physically tested to ensure the repairs have been completed effectively. As a group, conclusions are discussed highlighting improvements that could be made, and areas of the repair that have gone well. Feedback is given throughout the course and discussion is encouraged.