DMSC53 Resin Infusion Laminating & Light RTM

|

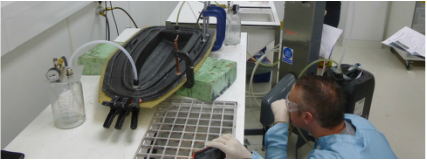

Resin infusion laminating and light resin transfer moulding are covered in a single course due to the similar nature of the processes yet distinctive merits. This course covers a full range of materials and processing techniques, giving an in-depth and hands on approach to understanding how the processes work and how they can be applied successfully.

|

|

Typical Attendees

This course suits lead technicians, supervisors, engineers, designers and researchers who are responsible for trials, development and tooling design associated with Resin Infusion laminating and Light RTM. Structure 35% theory, 65% practical, 12 delegates maximum, no experience required Price per Delegate

£ 2,040.00 (£ 1700.00 plus £340.00 VAT) |

|

Resin infusion & light resin transfer moulding course content

| DMSC53 | Session 1 09:00 - 11:00 |

Session 2 11:15 - 13:15 |

Session 3 13:45 - 15:45 |

Session 4 16:00 - 18:00 |

|---|---|---|---|---|

| Monday | Introduction Equipment issue Health & Safety Theory Introduction to composites theory, matrix, reinforcing & fabric materials |

Theory & Discussion Resin flow infusion Darcy’s Law and effects of permeability, flow channels, pressure dams, vacuum, temperature &,viscosity External distribution & infusion media & flow fronts |

Theory Demo & Practical Setting up & completing trial panels Resin calculations Vacuum bagging Vacuum bag materials & methods Leak detection & vacuum volume |

Demo & Practical Resin flow infusion trial panels using a range of laminate combinations, core materials, external,distribution & infusion media Theory & Discussion Sandwich panels Infusion core materials |

| Tuesday | Practical Infuse sandwich trial panels Theory & Practical Using trial panel information Designing infusion layout for parts |

Theory Demo & Practical Tooling care, preparation & release agents Practical Lay-up a resin flow infusion part into a complex female tool including gel coat application,fabrics, core material, external distribution & infusion media, surface,bagging & leak checking |

Discussion & Practical Resin calculations for parts Predicting flow fronts & infusion times Final resin flow infusions of parts with external media |

|

| Wednesday | Theory Internal infusion media and light resin transfer moulding (Light RTM) Reinforcing fabrics &,core materials |

Practical Resin flow infusions with,a range of internal media, reusable silicon vacuum bags & semi-rigid closed moulds |

Theory Reusable silicon vacuum bags Semi-rigid closed moulds Creating seals, connections and resin channels |

Theory, Demo & Practical Design of mould seals, injection & vent points Application of calibration wax, injection & vent point connections & profiles |

| Thursday | Theory, Demo & Practical Resin film infusion Material life, storing, defrosting, handling, templating & application |

Practical Use resin film laminating to produce a semi-rigid closed mould to be used for producing light RTM parts |

Demos & Practical Envelope vacuum bagging Theory & Practical Curing resin filmsTemperature profiles |

|

| Friday | Demo & Practical Break out and prepare semi-rigid closed moulds for use |

Guided Practical Apply gel coat and apply reinforcement materials Prepare & use Light RTM equipment to produce parts |

Practical Break out parts Theory & Discussion Infusion causes of & identifying defects & relate to parts produced |

Reinstate Workshop Written test Equipment return Summary / Feedback |

| DMSC53 Resin Infusion Laminating & Light RTM.pdf | |

| File Size: | 176 kb |

| File Type: | |

Frequently asked questions

This course is suitable for technicians, supervisors, engineers, designers and researchers who are responsible for production, trials, development and tooling design with resin infusion and light resin transfer moulding (RTM). We cover approximately 26 hours of practical throughout the week.

|

Resin infusion laminating is split into two distinct categories; resin flow infusion and resin film infusion. The course begins by looking at the resin flow infusion method and the various factors that influence resin flow. You will learn about the practical implications of Darcy’s law (fluid flow through the medium) in terms of flow channels, pressure dams, vacuum, temperature, viscosity and effects of permeability. All of these factors are discussed in theory sessions and then applied to produce trial panels, using different external infusion media and fabrics. |

Next we look at core materials and their uses, applications and limitations. Working with suitable core materials you will produce additional infusion trial panels and use this information to produce an infusion strategy to predict flow fronts your components. This will highlight the advantages of using core materials, for strength and weight saving, and how it will affect the infusion strategy. The trial panel information is then used to plan and infuse a detailed component, mapping the trial information onto the part, to highlight any discrepancies that occur during the infusion and their causes.

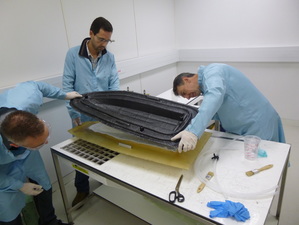

We then move onto conducting resin infusions using a wide range of internal media and reinforcement fabrics. By using re-usable vacuum bags as well as semi-rigid closed tooling, you learn how single and double sided parts can be very quickly produced for higher volume production. This highlights the differences with external and internal media, as well as flow characteristics and positioning of resin entry and vent points. This leads to an understanding of the differences between Resin Infusion and Light Resin Transfer Moulding.

Mould design is key when producing closed moulds for infusion and light RTM and we move on to producing closed moulds using calibration wax, designing and creating mould seals and resin channels, and planning and preparing injection and vent points.

You will then use the film infusion process to make a semi-rigid closed mould to produce parts using RTM. We will show you the tiling method for producing composite moulds, used to prevent distortion when curing and using the mould at elevated temperatures. The mould will be vacuum bagged, oven cured overnight and broken out the next morning. The mould halves are then trimmed, finished, fitted out and released to make them ready to use for production of a Light RTM part.

We then move onto conducting resin infusions using a wide range of internal media and reinforcement fabrics. By using re-usable vacuum bags as well as semi-rigid closed tooling, you learn how single and double sided parts can be very quickly produced for higher volume production. This highlights the differences with external and internal media, as well as flow characteristics and positioning of resin entry and vent points. This leads to an understanding of the differences between Resin Infusion and Light Resin Transfer Moulding.

Mould design is key when producing closed moulds for infusion and light RTM and we move on to producing closed moulds using calibration wax, designing and creating mould seals and resin channels, and planning and preparing injection and vent points.

You will then use the film infusion process to make a semi-rigid closed mould to produce parts using RTM. We will show you the tiling method for producing composite moulds, used to prevent distortion when curing and using the mould at elevated temperatures. The mould will be vacuum bagged, oven cured overnight and broken out the next morning. The mould halves are then trimmed, finished, fitted out and released to make them ready to use for production of a Light RTM part.

|

You will then use internal infusion media with the Light RTM process. Mould halves are gel coated and the dry fabrics and infusion media are sealed inside the semi-rigid mould halves. You will determine resin quantities required and learn to setup, check and operate a Light RTM injection pump. Resin is then injected into the closed mould under pressure and with the aid of a vacuum the Light RTM part produced.

The course is concluded by assessing the components which have been produced. You will learn how to identify defects, their causes and possible solutions and how to produce the best quality Resin infused composite parts. |