Pencil & Die Grinders

When you need to dress back intricate edges, cut outs or the surface of a laminate or sandwich panel, these tools are the most effective for fine and intricate operations.

All these kits are supplied with a selection of diamond burrs that are suited to grinding a range of thermoset composite materials.

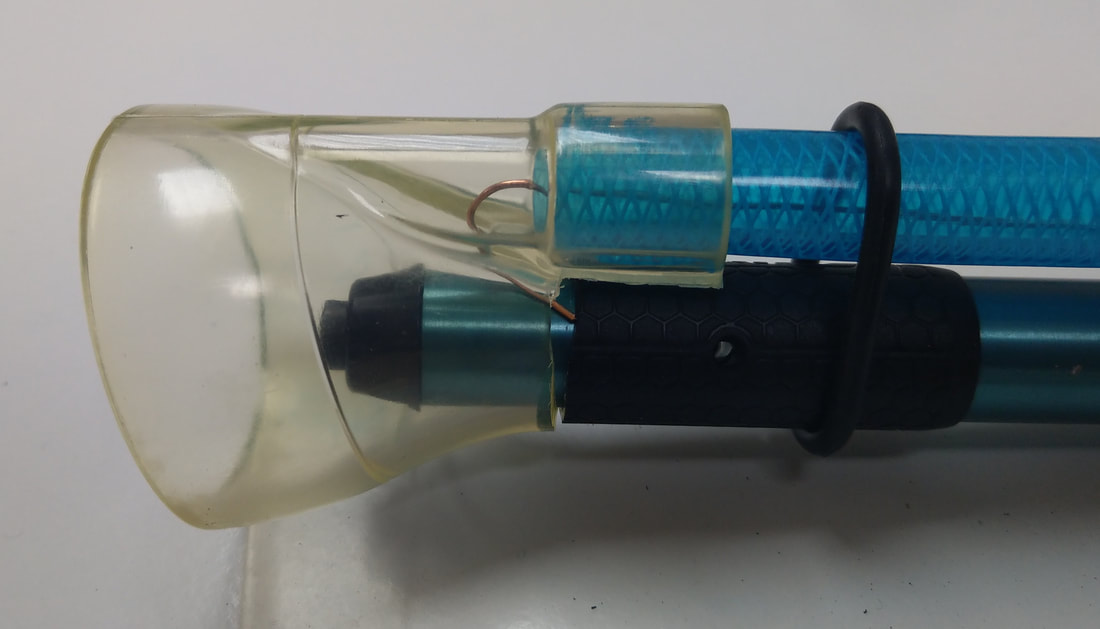

The extracted tools are very effective at dust capture at source to make for a clean working environment.

All these kits are supplied with a selection of diamond burrs that are suited to grinding a range of thermoset composite materials.

The extracted tools are very effective at dust capture at source to make for a clean working environment.

DMP0141

|

DMP0143

|

DMP0135

|

DMP0136

|

|

DMP0140

|