DMSC58 Composite Repair - Stage 1

|

This course provides comprehensive training, understanding and application of a full range of repair techniques to composite mouldings, from cosmetic through to structural repairs. Emphasis is on understanding failure modes, recognising materials and production process, and correct use of tools, abrasives and dust extraction in order to apply effective repairs. |

|

Typical Attendee

This course is suitable for anyone involved with repairs to composite materials, including repair technicians, supervisors, engineers, designers, researchers and managers. Structure 30% theory, 70% practical, 10 delegates maximum, no experience required. Price per Delegate

£ 2,400.00 (£ 2,000.00 plus £400 VAT) |

|

Special Notice

As training providers it is our responsibility to ensure training is up to date and taught to the highest standard. To assist with this we have aligned our repair courses with the requirements of the SAE’s AIR4938 standard, 'Composite and bonded structure technician/specialist training document'. This standard was produced by the worldwide 'Commercial Aircraft Composite Repair Committee' (CACRC) and defines the foundation content and structure for composite repair training that is applicable to all industry sectors.Our stage 1 and 2 composite repair courses already covered cross sector repair techniques with a full range of materials, processes, tools and techniques and were already 90% in line with the AIR4938 standard. As all our courses are already in line with the UK’s National Occupational Standards for composites and fully documented to the UK’s Qualifications and Curriculum Authority requirements, it was a relatively easy task to cross reference to the AIR4938 standard and add 10% more technical content to our repair courses. The end result is that all our customers benefit from the work we do for aerospace.

As training providers it is our responsibility to ensure training is up to date and taught to the highest standard. To assist with this we have aligned our repair courses with the requirements of the SAE’s AIR4938 standard, 'Composite and bonded structure technician/specialist training document'. This standard was produced by the worldwide 'Commercial Aircraft Composite Repair Committee' (CACRC) and defines the foundation content and structure for composite repair training that is applicable to all industry sectors.Our stage 1 and 2 composite repair courses already covered cross sector repair techniques with a full range of materials, processes, tools and techniques and were already 90% in line with the AIR4938 standard. As all our courses are already in line with the UK’s National Occupational Standards for composites and fully documented to the UK’s Qualifications and Curriculum Authority requirements, it was a relatively easy task to cross reference to the AIR4938 standard and add 10% more technical content to our repair courses. The end result is that all our customers benefit from the work we do for aerospace.

Composite repair 1 course content

| DMSC58 | Session 1 09:00 - 11:00 |

Session 2 11:15 - 13:15 |

Session 3 13:45 - 15:45 |

Session 4 16:00 - 18:00 |

|---|---|---|---|---|

| Monday | Introduction Equipment issue Health & Safety Theory Introduction to composites theory, materials & processes |

Theory & Discussion Damage detection Repair of composites overview Theory, Discussion & Demo Dust generation, risk assessment & capture |

Theory & Discussion Material removal tools & abrasives Theory, Demo & Practical Non-structural cosmetic & temporary repairs |

Theory, Demo & Practical Wet lay-up laminating Matrix preparation, application, curing & exotherm control Application of cosmetic gel coat repairs Application of temporary repairs |

| Tuesday | Demo & Practical Sanding and polishing of cosmetic gel coat repairs Re-filling of cosmetic gel coat repairs Assessment of temporary repairs |

Theory, Practical & Discussion Failure modes & predicting failure Impacts & assessment of damage Theory Minor and major structural laminate repairs |

Demo & Practical Removal of temporary repair Preparation of tapered/scarf surfaces Preparation of single & double sided repair surfaces |

Theory, Demo & Practical Temporary backing structures Process & material matching & preparation |

| Wednesday | Theory, Demo & Practical Wet lay-up laminating of single & double sided, minor & major structural repairs |

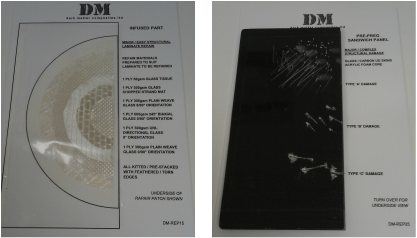

Theory & Demo Structural sandwich panel repairs Core preparation & splicing Practical Preparation of type A, B & C structural sandwich panel repair surfaces & materials for infused & pre-preg panels |

Theory & Demo Vacuum bagging & materials Caul plates Demo & Practical Wet lay-up & vacuum bagging of type A/B structural repairs |

|

| Thursday | Demo & Practical Recognition & orientation of pre-preg materials Laminating of type B/C structural pre-preg sandwich panel repairs |

Theory & Practical Curing pre-preg repairs Temperature & pressure profiles Tg points Use of hot bonder for curing pre-preg repairs |

Discussion & Practical Inspection, evaluation and review of repairs completed Destructive testing of repairs |

Assessed Practical Assessment of damage Complete a repair strategy Preparation of repairs |

| Friday | Assessed Practical Completion of repairs to a range of test piece components, including step sanded surface preparation, identification of laminate plies, preparation & application of orientated materials, vacuum bagging, curing, surface finishing, blending and polishing |

Reinstate Workshop Written test Equipment return Summary / Feedback |

||

| DMSC58 Composite Repair Stage 1.pdf | |

| File Size: | 176 kb |

| File Type: | |

Composites repair 1 course content:

This course will give you the knowledge and skills you need to get you started with composite repairs. It is aimed at anyone involved with repairs to composite materials, including repair technicians, supervisors, engineers, designers, researchers and managers. No previous experience is required

The course will cover approximately 28 hours of practical throughout the week and 12 hours theory and practical demonstrations.

The course will cover approximately 28 hours of practical throughout the week and 12 hours theory and practical demonstrations.

|

All the components for repair will be supplied to you, ready made as this ensures consistency of the components, maximising your time repairing various forms and working with a selection of materials. You will damage these parts and then complete 8 composite repairs, ranging from cosmetic through to structural repairs where damage has gone through the component. These include working with gel coat repairs for a perfect finish, sandwich panel repairs, pre preg, temporary and then permanent repairs. |

|

We will look at the reasons why composite components fail, for example; delamination, disbonds and fibre breakage and the types of damage including impact and puncture damage. You will cover material identification, the type of fabric and fibre being used, identifying the production method and working out how best to go about the repair.

Before you begin the assessment task, all the training tasks completed will be reviewed and discussed in the group. Destructive testing will be carried out on the structural repairs to inspect their integrity. |