Step Sanding Tool KitsOur 'Step Sanding Tool Kits’ allow step sanded repair surfaces in composite parts to be prepared in less time than scarf surfaces and can be used cross sector, including civil, marine, automotive and aerospace repairs, to name a few.

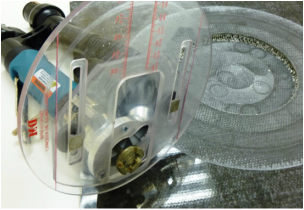

The combination of Dynabrade air routers with diamond surface planing heads and flexible jigs accommodate step sanded repair surfaces on parts with internal and external double curvature. The laser engraved jigs accommodate metric and imperial scales for both radii and diameters. |

|

Consistent step sanded repair surfaces can be produced on composite parts with significant time saving, typically 50-75% time saving over current practices.

Paired with one of our portable dust extraction units, the on-tool extraction is highly effective at removing the dust generated at point of source, to the extent that it eliminates the need for containment curtains and dust masks during the surface preparation activity.

Paired with one of our portable dust extraction units, the on-tool extraction is highly effective at removing the dust generated at point of source, to the extent that it eliminates the need for containment curtains and dust masks during the surface preparation activity.

High end step sanded composite repairs into the realms of standard repair practices at significantly reduced cost, we have an ‘Off the Shelf Solution’

|

Each kit includes:

|

In the News

| ||||||||||||

DMP0111

|

DMP0110

|