|

Typical Attendees

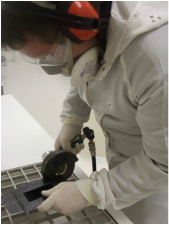

This course is suitable for anyone involved in both manual and CNC trimming, finishing and assembly of composite parts, including technicians, supervisors, engineers, designers, researchers and managers. Our Aim We are afraid to say that there is no 'Speeds and Feeds' tables for composite materials due to the wide material combinations available. We will show you how to select the right tools and cutting heads for the right job and how manual methods can provide insight on how CNC methods can be applied effectively. Structure 30% theory, 70% practical, 8 delegates maximum, no experience required Price per Delegate

£ 2,400.00 (£ 2,000.00 plus £400 VAT) |

|

Trimming, Finishing and Assembly of composites course content

Trimming, Finishing and Assembly of composites course content

| DMSC57 | Session 1 09:00 - 11:00 |

Session 2 11:15 - 13:15 |

Session 3 13:45 - 15:45 |

Session 4 16:00 - 18:00 |

|---|---|---|---|---|

| Monday | Introduction Equipment issue Health & Safety Theory Introduction to composites theory, materials & processes |

Theory Types, uses & control of engineering sketches & drawings Practical Interpreting & extracting information from engineering sketches & drawings |

Theory & Demos Identifying materials and processes used for composite parts Safe handling of unfinished parts Theory & Demos Measuring & marking out composite parts |

Practical Measure & mark a range of features on a range of composite parts/materials using surface tables, height gauges, scribes, rules & jigs |

| Tuesday | Theory & Demo Trimming, sanding & finishing overview Cutting & abrasive materials & grades Planning operation sequences |

Theory & Demo Safe use of air and electrical power tools Dust generation, control & extraction Defects caused by trimming activities |

Theory & Demos Setting up & safe use of band saws, disc cutters, routers and saws Edge damage and de-lamination Practical Cut a range of profiles in a range of composite parts/materials using a range of tools and jigs |

|

| Wednesday | Theory & Demos Filing & sanding composite materials Edge & surface finishing Setting up & safe use of linishers, disc sanders, die grinders, belt sanders & orbital sanders Practical Final shaping and surface finishing of a range of features in a range of composite materials using range of tools and jigs |

Theory & Demos Drilling & boring composite materials Break through, laminate,support and back drilling Setting up & safe use of pedestal drills, low speed and high speed hand drills Practical Drill & bore a range of hole features in a range of composite parts/materials including small/large holes, counter sinks, counter bores, inserts, carbide & diamond tips, hand & pillar drills, drill jigs |

||

| Thursday | Theory, Demos & Practical Cleaning & polishing composite materials using compounds, abrasives & polishers |

Theory, Demos & Practical Composite assemblies Adhesive bonding Surface preparation Peel plies Adhesive application & curing |

Discussion & Practical Inspection, evaluation and review of all activities completed Assessment Briefing |

|

| Friday | Assessed Practical Fully trim, drill, finish and assemble a range of test components accurately to drawings Including planning operations, selection of correct tools, cutting heads & abrasives, effective techniques & final assembly of the parts |

Reinstate Workshop Written test Equipment return Summary / Feedback |

||

| DMSC57 Trimming, Finishing & Assembly of Composites.pdf | |

| File Size: | 175 kb |

| File Type: | |

|

This course will give you comprehensive training, understanding and application of a full range of trimming, finishing and assembly techniques associated with composite parts. It is suitable for anyone involved in manual and CNC trimming, finishing and assembly of composite parts, including technicians, supervisors, engineers, designers, researchers and managers.

There are no speeds or feeds tables for composites due to the range of material that can be in the part. The focus of this course is to select and use the right tools, abrasives, cutters and technique for the best results. |

With a methodical and ordered approach through the week, new skills, tools and processes are introduced, giving you the confidence to try new equipment. We will show you how best to plan composite trimming and assembly activities, covering composite theory, alongside approximately 28 hours of hands on practical.

The course begins with interpreting technical information from engineering drawings. This information can then be applied to your assembly allowing you to plan and work systematically, from measuring and marking, to bonding the completed assembly together. You will mark a range of component features, for example concave and convex surfaces, radii, multiple drill holes and parallel lines using a range of equipment such as height gauge, surface table, scribes, calipers, rules and jigs.

The course begins with interpreting technical information from engineering drawings. This information can then be applied to your assembly allowing you to plan and work systematically, from measuring and marking, to bonding the completed assembly together. You will mark a range of component features, for example concave and convex surfaces, radii, multiple drill holes and parallel lines using a range of equipment such as height gauge, surface table, scribes, calipers, rules and jigs.

|

The final stage in the process is finishing, where you will be cleaning and polishing your components. Working through a range of abrasives and cutting compounds you will learn how to best achieve the required finish.

Cutting and trimming follows, with the introduction of air tools and how best to control dust generation, in line with good health and safety practices. Emphasis is placed on the safe and effective use of tools and abrasives. After demonstrations you will get to find which tool and abrasives work best. Under the guidance of our experienced tutors you will be working with different materials and features. You will use band saws, bench mounted disk and belt sanders and a range of air driven hand tools, including die grinders, cut off wheels, routers and belt linishers. These all come with their own range of silica carbide or diamond abrasives to try. Drilling, boring and countersinking are completed with diamond bits to get the best results. Laminate supports and high speed drills offer solutions for minimising break through and localised delamination. |

The final stage in the process is finishing, where you will be cleaning and polishing your components. Working through a range of abrasives and cutting compounds you will learn how to best achieve the required finish.