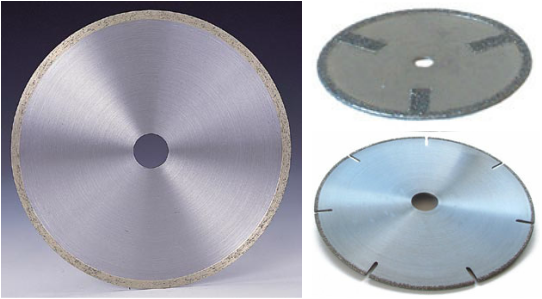

Cut-Off Wheels

When you need to cut through a thin or thick laminate or sandwich panel very quickly, these tools are the most effective when it comes to speed of cut and finish.

The diamond discs are well suited to thermoset composite materials and the 3M GreenCorps discs are highly effective over a wide range of materials.

The extracted tools are very effective at dust capture at source to make for a clean working environment.

The diamond discs are well suited to thermoset composite materials and the 3M GreenCorps discs are highly effective over a wide range of materials.

The extracted tools are very effective at dust capture at source to make for a clean working environment.

DMP0130

|

|

DMP0131

|

DMP0139

|

DMP0146

|