|

Typical Attendees / Pre-requisite

This is a high end course and delegates will need to have a sound technical background in materials, engineering or design, or have relevant experience, please call or email us if you are unsure which course is best for you. Structure 60% theory, 40% practical, 10 delegates maximum, no experience required Price per Delegate

£ 2,040.00 (£ 1700.00 plus £340.00 VAT) |

|

Composites for engineers and designers 1 course content

| DMSC61 | Session 1 09:00 - 11:00 |

Session 2 11:15 - 13:15 |

Session 3 13:45 - 15:45 |

Session 4 16:00 - 18:00 |

|---|---|---|---|---|

| Monday | Introduction Equipment issue Health & Safety Measures & Legislation Theory & Discussion Composites history Composites theory |

Theory & Discussion Matrix materials Reinforcing materials Fabric types Laminate theory and ply orientation Lay-up specifications |

Theory & Discussion Sandwich structures Core materials Processing composite materials Theory & Practical Tooling care and preparation Release agents |

Theory & Guided Practical Wet lay up laminating Design a laminate to suit a load requirement Production of a wet lay-up part including calculations, gel coat & laminate application |

| Tuesday | Theory Resin flow & film infusion laminating External & internal media with vacuum bagged & closed moulding Demo & Practical Trial panels & evaluation |

Theory & Discussion Vacuum bagging Bagging materials & methods Leak detection Guided Practical Design of distribution media for resin flow infused part |

Guided Practical Gel coating, application of fabrics, external distribution and infusion media, surface vacuum bagging and leak detection of resin flow infusion part |

Practical & Discussion Resin calculations Predicting flow fronts & infusion times Final resin flow infusion and evaluation of parts Demonstration Resin film infusion laminating |

| Wednesday | Theory, Demo & Guided Practical Pre-preg laminating Material templating ply orientation, nesting & kitting Design a laminate to suit a load requirement |

Theory Processing & preparation of core materials Guided Practical Pre-preg laminating of part with sandwich structure |

Demo & Practical Envelope vacuum bag & cure pre-preg part Theory Matrix curing & post-curing, temperature & pressure profiles Tg points |

Theory & Videos Resin transfer moulding Hot press moulding Filament winding Pultrusion Automated tape laying & fibre placement |

| Thursday | Theory & Discussion Causes of and identifying defects Manual & NDT inspection Production & quality controls In-service monitoring |

Theory, Demos & Practical Breakout parts produced Trimming & finishing composites |

Theory & discussion Adhesion & bonding methods Theory & Demos Failure modes Re-work & repair principles Repair techniques |

Guided Practical GRP and pre-preg repair including removal of damage, preparation of the repair surface & laminating of repairs Reinstate Workshop |

| Friday | Theory & Discussion Tooling and component design principles, types materials & life Re-cycling & environmental issues |

Practical & Discussion Case studies for tooling and component designs & problem solving |

Theory & Discussion Laminate calculations Finite element analysis Testing composites On-line resources |

Written test (1hour) Equipment return Summary / Feedback |

| DMSC61 & 62 Composites for Engineers & Designers Courses.pdf | |

| File Size: | 185 kb |

| File Type: | |

|

Although no previous composites experience is required for this course you will need to have a sound technical background in materials, engineering or design, or have relevant experience. Understanding and applying the design principles for the various composites materials and processes is the primary focus on this course.

The course will give you an intensive and technical overview whilst providing an intuitive approach to composites that forms a strong foundation to develop from. During the theory sessions we will introduce the manual composites processing methods starting with wet lay-up, then infusion and finally pre-preg. |

|

We look at how wet lay-up is used and the characteristics of the process. You will then be given a design brief and supplied with materials. Your task is to meet the specification and make the part applying what you understand of the materials. These parts are laid up by hand with brushes and rollers to wet out and consolidate the materials.

After this we move onto a resin infusion task. Following the theory session, you will work in groups to produce a trial panel using the flow infusion method. Each group will work with different external infusion media and either stitched, bonded or woven fabrics. The results from the trial panel are discussed and used to design an infusion strategy for the final component. |

The final process you will use is pre-preg laminating. This encompasses a new range of skills and builds on from the theory of the previous composite processes. We will look at the importance of pre-preg material handling and preparation which includes defrosting, producing templates, nesting, kitting materials and ply orientation. At this stage composite sandwich structures are introduced adding an additional range of properties to consider in the design of another part. These parts are envelope bagged and cured in an autoclave.

|

Curing theory allows you to programme your own autoclave cure cycle. Interpreting information from the technical data sheet you will be able to produce a suitable heat and temperature cure profile, allowing for a glass transition temperature (Tg) for in service use.

Automated processes are covered in the classroom with the aid of videos and theory. Each process; resin transfer moulding, hot press moulding, filament winding, pultrusion, automated tape laying and automated fibre placement is explained highlighting their applications, limitations and advantages. The components that have been produced are broken out of the moulds, trimmed and inspected. As a group you will discuss the components to fully understand where mistakes have been made, and how they could have been prevented. From basic manufacturing defects to design errors, this session brings together the work covered so far. |

|

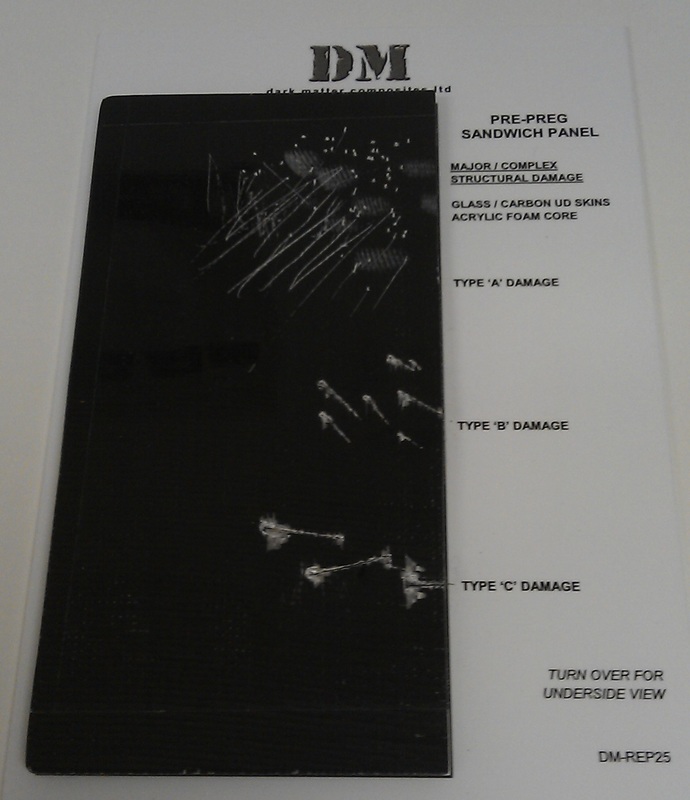

We move onto failure modes and repair techniques, gain an understanding of the types of damage composite components suffer and introduce controlled damage into parts. The damaged material is removed and a scarf repair is used to make good the impaired area.

The final day of the course brings together all of the principles covered in the week, in relation to the design of composite tooling and parts, using case studies to demonstrate the concepts used in composite design. |

This course will accelerate anyone’s knowledge and understanding of composites and will aid in technical communication in the composites arena.