|

Typical Attendees

This course is suitable for anyone involved with processing pre-preg and core materials to produce strong lightweight parts, including pre-preg laminators, technicians, supervisors, engineers, designers, researchers and managers. Pre-requisite Attendees must have previously completed the course DMSC54, pre preg laminating – Stage 1 Structure 25% theory, 75% practical, 10 delegates maximum Price per Delegate

£ 2,040.00 (£ 1700.00 plus £340.00 VAT) |

|

Pre preg laminating stage 2 course content

| DMSC55 | Session 1 09:00 - 11:00 |

Session 2 11:15 - 13:15 |

Session 3 13:45 - 15:45 |

Session 4 16:00 - 18:00 |

|---|---|---|---|---|

| Monday | Introduction Equipment issue Theory & Demos Refresh of composite theory & materials Sandwich panel theory Core materials |

Theory Adhesive Bonding Peel plies Two/double stage processing Practical Laminate first skin, for 2 stage lay-up including peel ply, vacuum bagging & curing |

Theory & Demo One/single stage processing Preparation of nomex & aluminium honeycomb core materials Resin film application Core splicing |

Practical Laminate one/single stage core lay-up on curved tool, including honeycomb materials, de-bulking, core splicing, vacuum bagging & curing |

| Tuesday | Theory, Demo & Practical Processing foam and syntactic core materials Thermoforming foam Demo & Practical De-bag & preparation of first skin |

Practical Preparation and fitment of honeycomb, foam, syntactic core and core splicing over internal, external, acute & radius corners |

Theory & Demo Caul plates with core processing Practical Processing hard pads & inserts into sandwich panels |

Practical Laminating of closing skins for two/double stage lay-up Vacuum bag & cure |

| Wednesday | Theory Three/triple stage processing Practical Laminate, vacuum bag & cure outer skin for three/triple stage lay-up |

Theory & Demo Inserts, hard pads with core processing Practical Laminate, vacuum bag & cure inner skin for three/triple stage lay-up |

Practical Prepare outer & inner skins, laminate resin film, fit & splice core, fit and pot inserts for a closed mould three/triple stage lay-up Vacuum bag and autoclave cure for closed mould three/triple stage lay-up |

|

| Thursday | Demo & Practical De-bag & de-mould all parts produced Theory & Discussion Process control & inspection |

Theory & Discussion Causes of & identifying defects Inspection of parts produced |

Assessed Practical Laminate complete part including material preparation, multi-stage laminating and processing, split tooling, inserts, various core materials & vacuum de-bulking |

|

| Friday | Assessed Practical Complete assessed practical, vacuum bagging, autoclave loading & curing |

PracticalDe-bag & de-mould assessment part Safe edge all parts produced |

Reinstate Workshop Written test Equipment return Summary / Feedback |

|

| DMSC55 Pre-preg Laminating Stage 2.pdf | |

| File Size: | 175 kb |

| File Type: | |

|

Pre-preg Laminating Stage 2 course content:

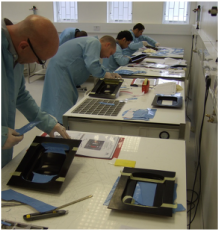

This course is suitable for anyone involved with processing pre preg and core materials to produce strong lightweight parts, including pre preg laminators, technicians, supervisors, engineers, designers, researchers and managers. You must have previously completed the course DMSC54, (pre preg laminating – Stage 1) as there is only a 30 minute recap of the stage 1 course. We cover approximately 31 hours of practical and 9 hours of new theory and technical demonstrations. |

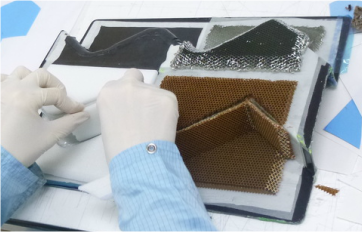

Building on what was covered in our stage 1 course, the focus now moves onto core materials. At the start of the course you will address core identification, orientation and core splicing. You will produce your parts using Nomex and aluminium honeycomb, foam and syntactic cores. Attention to detail is vital as you will need to produce templates, trim, chamfer and fit the core materials.

Multiple stage curing of your parts and vacuum de bulking will be covered through the course. From a single stage cure to a 3 stage closed mould cure, you will see how the curing process effects the quality of the components.

|

As composite parts can be scrapped at any point in the manufacturing process, being methodical and organised will greatly improve the quality of the components produced. You will be guided through the processes and given support throughout the week, inspecting all the parts produced and assessing the causes of any underlying defects. During the course you will complete 4 practical tasks, 3 training tasks and 1 assessment task. This is a fast paced course. As you will have a good grounding from DMSC54, pre preg stage 1, the laminating time and vacuum bagging time is significantly reduced. This allows you more time to develop your skills by producing parts with cores and sandwich panels. |

The final training task addresses pre preg skin preparation and the use of inserts with core materials. At the end of the week you will complete a practical assessment task along with a written test. This course will give you good understanding of pre preg sandwich structures and hands on experience working with a range of core materials, commonly associated with pre preg.