Carbon fibre gets used for a lot these days, sometimes it’s for all the right reasons & it’s designed and fabricated well, other times it’s not. Here at Dark Matter Composites we love looking at new and fun developments in the world of composites, as well as the more serious stuff. This week's caught our eye and is well worth a look, particularly if you (are old enough to) remember the excitement about VTOL on the Harrier, (or nerdy enough) to love Science fiction or play with remote control models.

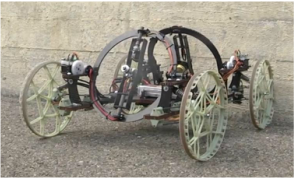

| Disney uses carbon fibre to create wall-climbing robot https://www.disneyresearch.com/publication/vertigo/ https://youtu.be/KRYT2kYbgo4 |

In particular we loved the two tilt-able propellers that provide thrust to propel it on horizontal and vertical surfaces. It's nimble and lightweight design made us wonder what it's future applications may be, especially as can it travel along ceilings upside down.

Then we started analysing the design, with comments like 'what a lot of excess carbon fibre, fixtures and fittings!' Rodney is sure he could loose half of it, in particular, make the suspension in a single sprung piece, use a little bit of core on the motor mounts and rings.... you get the picture. Although he did have special commendation for the controls/software engineers.

Then we started analysing the design, with comments like 'what a lot of excess carbon fibre, fixtures and fittings!' Rodney is sure he could loose half of it, in particular, make the suspension in a single sprung piece, use a little bit of core on the motor mounts and rings.... you get the picture. Although he did have special commendation for the controls/software engineers.

RSS Feed

RSS Feed