| It's that time of year again where seasonal over indulgence has knowingly reached a peak and under indulgence (diet, dry January?) is the most common thought each time your open the fridge or freezer - except if your freezer is full of rolls of pre-preg! January is one of the few times in the year when we get to revamp our facilities prior to the onslaught of back to back courses. A quick check of our walk-in pre-preg freezer has just reminded me of how many unusual projects we were involved in last year, especially as we have more stock of unusual project specific material than our standard pre-preg. Most of this is due to the number of training and consultancy projects we took on that involved training ourselves and others in using unusual materials. |

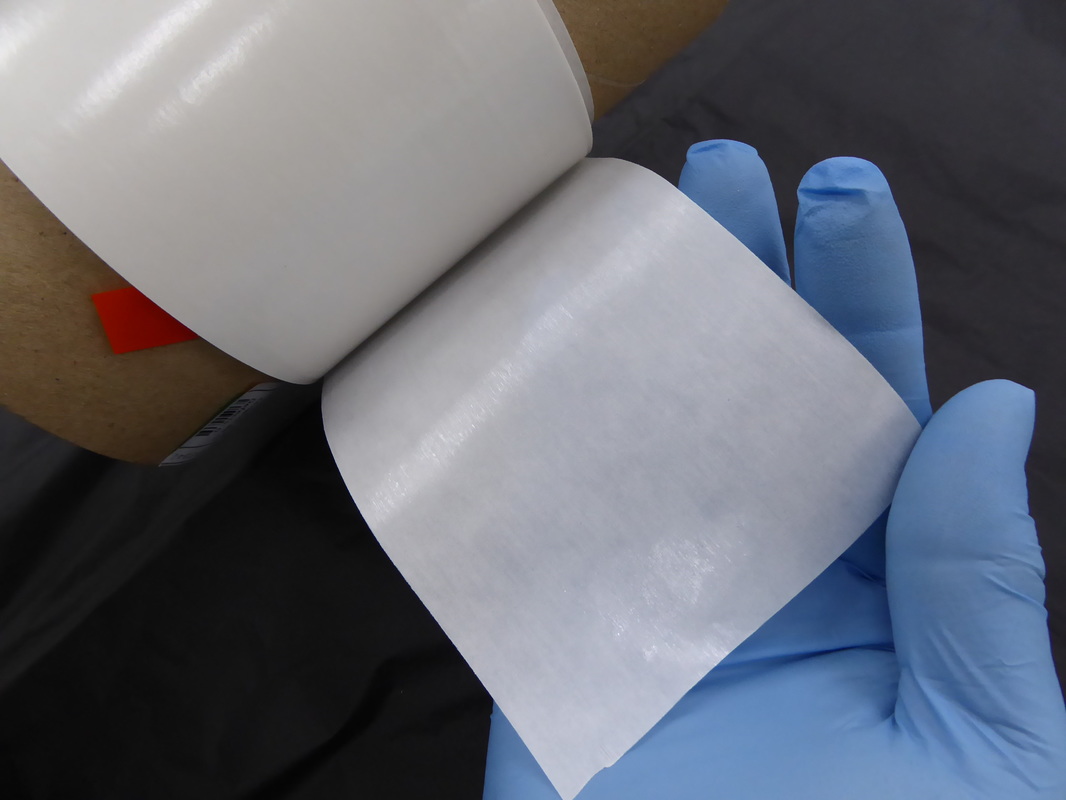

The most notable being the use of North Thin Ply Technology's very lightweight uni-directional materials to produce some complex prototype parts. When we placed the order for the materials, we were aware that the material was commonly used with tape laying machines, but we had to lay up complex parts by hand. It was lightweight UD so how bad could it be? Before we knew it, tooling was produced and the materials arrived, then the fun began! An initial play with 40gsm carbon and 26gsm quartz UD left us thinking 'how the hell are we going to do this?' especially when you can barely see the 26gsm quartz UD on white backing paper.

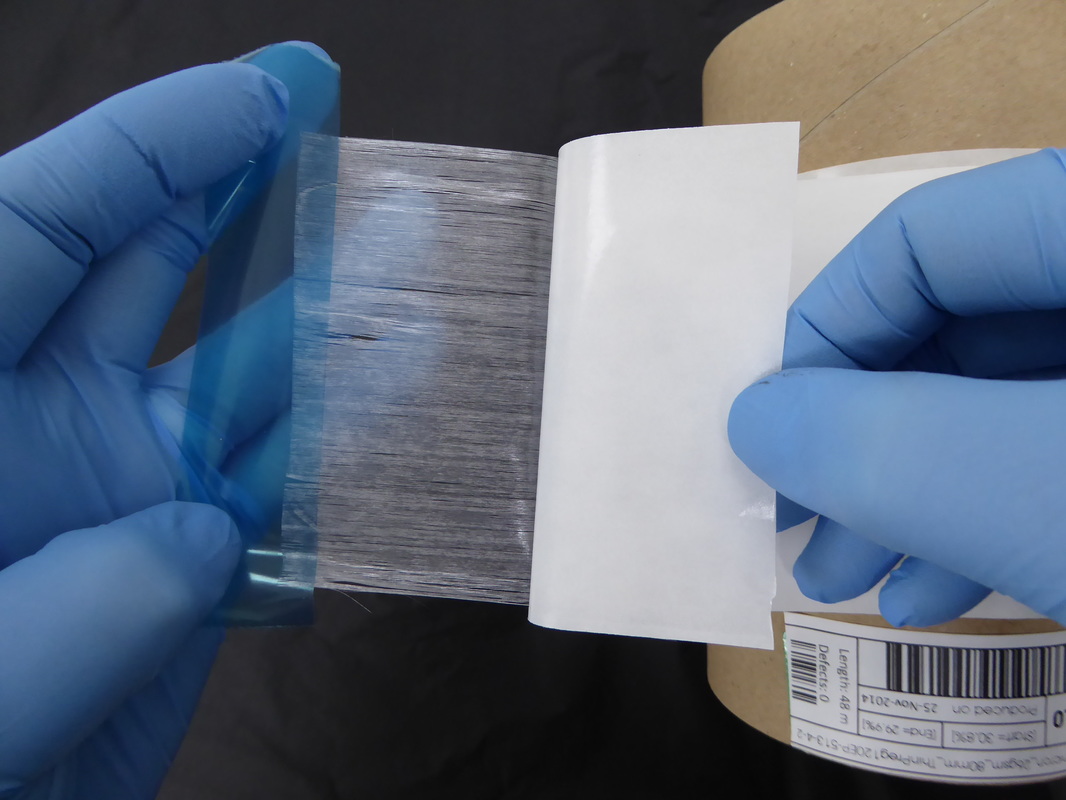

The first issue was working out how to get the material off the backing paper without it falling apart. A very sharp scalpel, engineers scribe and some flash tape solved the issue for both the carbon and quartz, (things were looking up).

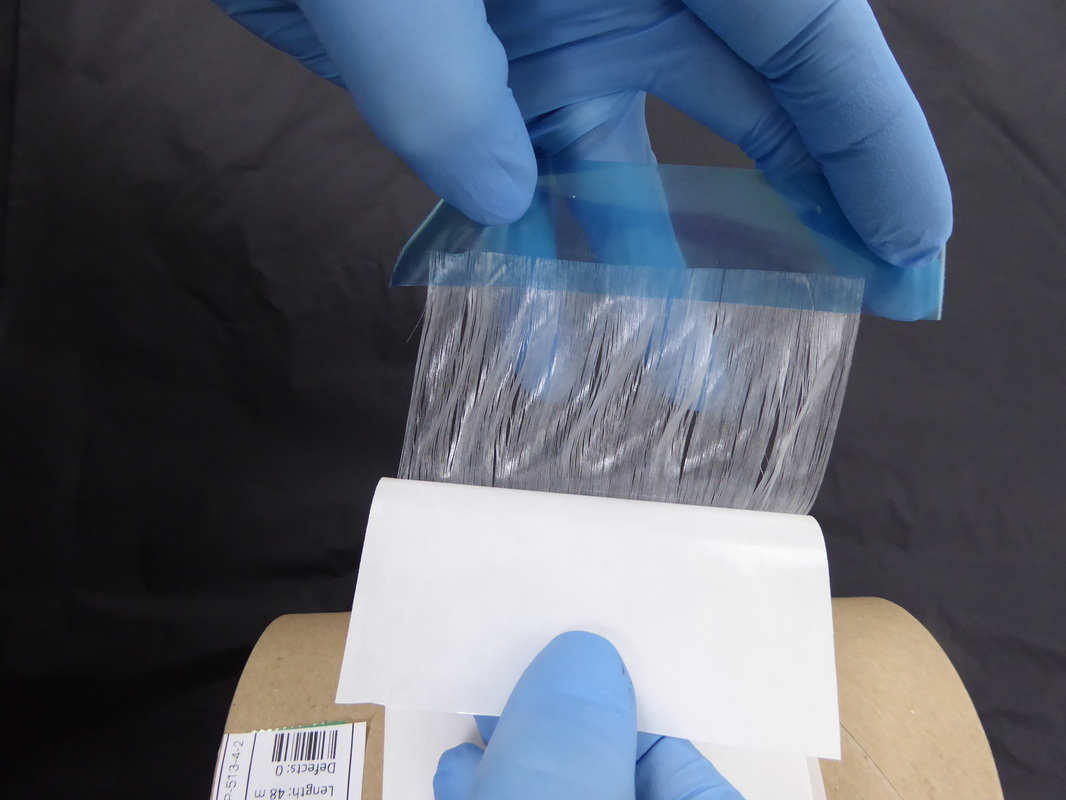

Next the big surprise, it was relatively easy to handle the material and conform it to the shape of the mould, (a bit of relief and a little smile then sets in).

The next even bigger surprise was the ability to layup a section in a single piece and loose several joins, the laminate design was getting simpler, (bigger smile!)

Our only issue was once the material was down, it was really stuck down. Trying to see where a piece ended was only clear if the material was poorly orientated, (which of course we would never do) so reference points were added to the tool with a pile of coloured pens and thick notepad kept close at hand as well as a camera.

For all those that know us, you will fully appreciate that we often work on weird and wonderful projects. We relish being out of our comfort zone and really believe that the experience of working with a wide rage of materials is important to technicians, engineers and designers. The industry keeps on developing and we need to keep up with change and keep looking for new and creative solutions.

If you need training on hand laminating with these materials please give us a call, although don't be surprised if we say we're going on holiday that day!

If you need training on hand laminating with these materials please give us a call, although don't be surprised if we say we're going on holiday that day!

RSS Feed

RSS Feed