That's the beauty of a metal car or bike. You can see how bad the damage is and you can easily decide if it is usable or not.

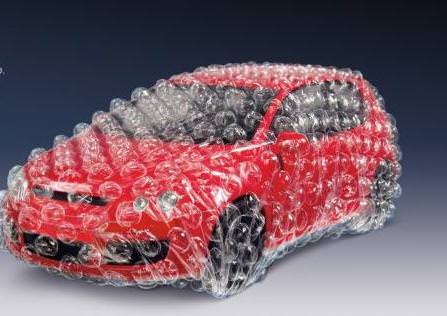

What happens when the car or bike isn't made of metal?

What happens when the car or bike isn't made of metal?

With the increasing use of carbon fibre this has become a much more important question.

A keen cyclist recently asked if there was an easy way to see the extent of the damage to their carbon frame. It had suffered a minor crash and looked OK, but they understood that didn't mean it was fine underneath. They wanted to know if it was worth paying for the check or would it just be written off anyway.

A keen cyclist recently asked if there was an easy way to see the extent of the damage to their carbon frame. It had suffered a minor crash and looked OK, but they understood that didn't mean it was fine underneath. They wanted to know if it was worth paying for the check or would it just be written off anyway.

The cyclist was right. We do need to look and see the extent of the damage to find out how much the composite structure has been weakened. Then we can assess the type of repair and associated costs involved. (This is one of the main reasons why another extremely keen and talented cyclist friend won't buy a carbon fibre bike).

Firstly we need to assess the damage, then decide how best to repair it. We need to remove the damaged material and put back new composite, ensuring we maintain the strength and integrity of the part. Finally, we ask if it's possible to prevent that damage happening in the future.

Over the last 10 years we have worked with an increasing number of aerospace companies, car manufacturers, boat builders, bike manufacturers, F1 teams and individuals looking at repair.

We have seen numerous developments in inspection equipment which have made it easier to see the extent of the damage. (if you aren't aware of these, have a look at this website:

JR technologies Ltd).

It is getting easier to assess the damage, but the quality of the repair was still highly dependent on the skill of the person conducting the repair.

We have seen numerous developments in inspection equipment which have made it easier to see the extent of the damage. (if you aren't aware of these, have a look at this website:

JR technologies Ltd).

It is getting easier to assess the damage, but the quality of the repair was still highly dependent on the skill of the person conducting the repair.

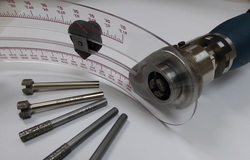

| It was these difficulties in consistency which lead to our developing our Step Sander. We spent years developing a tool, using our own experience and that of our customer's and course delegates, to produce a way of conducting faster (dust free repairs) even over curves. I won't tell you about it here, I'm sure you know about it already. (If you haven't seen it in action click here to see it). |

How easy is it to use, really?

Having never tried to make a composite repair I decided I'd better try using the tool myself. I've seen it in use (and I love PrePreg, including core & sandwich structures), but making parts isn't the same as repairing them.

My results weren't perfect, but they aren't too bad either and it took no time at all.

My results weren't perfect, but they aren't too bad either and it took no time at all.

There's a lot to learn about composite repair:

You need to know how to assess the damage

You need to know how a composite part is made in order to repair it (if you don't know, you need to know how to find out!)

You need to know how to remove the damage and replace the materials.

You need to do it safely (looking after yourself and any sensitive equipment like electronics).

You need to know how to cure those materials and finish the part to a high standard.

If any of this if of interest to you, come along to our Repair courses. We will show you how to do all this and more.

You need to know how to assess the damage

You need to know how a composite part is made in order to repair it (if you don't know, you need to know how to find out!)

You need to know how to remove the damage and replace the materials.

You need to do it safely (looking after yourself and any sensitive equipment like electronics).

You need to know how to cure those materials and finish the part to a high standard.

If any of this if of interest to you, come along to our Repair courses. We will show you how to do all this and more.

RSS Feed

RSS Feed