Did you go to the JEC in Paris last week? If you did what did you think about it? Most of the visitors and exhibitors loved the new venue. It was easier to walk around and everything was on one level.

| The only complaints we heard were how much everyone missed the social side of being in the centre of Paris. It wasn’t so much fun being on the outskirts. You either stayed at an airport hotel to get to the exhibition quickly in the morning, or had a more pleasant stay, but braved the commute. We think that work and pleasure should be combined, so braved the commute, which wasn’t too difficult, even with the French strikes. |

As always, we go to keep up to date with any new developments in technology as well as innovative ideas (the only way to keep a training course completely up to date is to know what’s happening). Our 2 days at the show didn’t really seem long enough to see everything and have impromptu meetings and catch up with customers and suppliers. If it gets any bigger next year we might have to stay for the full show.

Here are the award winners we especially liked:

Lightweight composite bipedal walker from UCHIDA Co. Ltd

This is an interesting, really uplifting story you can watch here on youtube.

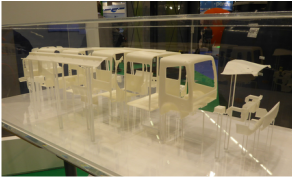

Modular, self-supporting, full composite bus body

This bus uses composite modules, which can be joined together, making it easier to produce buses of varying lengths. Simple, clever and using composites to their best advantage. We explained how much London relies on double decker buses rather than long buses (which get stuck around tight bends), so hopefully they will look at modules for taller buses too, it doesn’t hurt to ask...

Here are two pieces of technology that really impressed us and would be useful to a number of our customers:

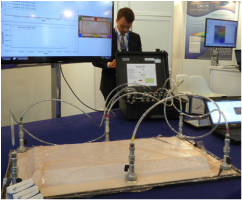

COHO Vacuum leak detection system

| Complex vacuum bagging of composites parts can be a bit of an art form, it’s the Marmite of the composites world, you love it or hate it and finding leaks is always time consuming. By using a network of vacuum connections and measuring flow rates at each, the software can estimate where a leak is, within 50mm. Once you fix one leak, the software then identifies the next until all leaks are found and fixed. At $45k US dollars, it’s expensive for most, but very cheap if you have high cost, complex parts or production critical timings then this kit could pay for itself in scrap reduction very quickly. |

Diamond Wire Saw – Really Impressive!

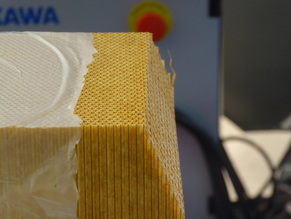

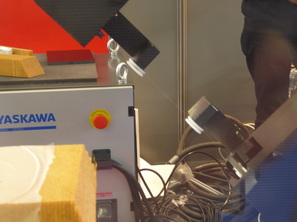

New to the composites market is this thin wire diamond wire saw from GTI. If you need to cut through fine materials such as thin laminates and honeycomb with chamfers, the cut and finish from this system was impressive. Although demonstrated attached to a robotic arm. If fitted to a tilting table, it can make manual honeycomb preparation really quick and easy with a nice neat cut line.

New to the composites market is this thin wire diamond wire saw from GTI. If you need to cut through fine materials such as thin laminates and honeycomb with chamfers, the cut and finish from this system was impressive. Although demonstrated attached to a robotic arm. If fitted to a tilting table, it can make manual honeycomb preparation really quick and easy with a nice neat cut line.

Lastly, to any of you new to composites you might want to contact Granta to have a look at their Composites design data software. It gives you access to materials data (allowing you to compare and select the most appropriate materials for your requirements), help answer material questions and improve communications.

All of the details for the award winners are on the JEC website: http://www.jeccomposites.com

RSS Feed

RSS Feed